Textile-integrated Electronic Systems

Textiles are an indispensable part of our everyday life. They are not limited to clothing made of fabric, knits and fleece, but also include technical textiles and composite materials. They withstand extreme stresses during washing and have many different functions while being light and highly flexible.

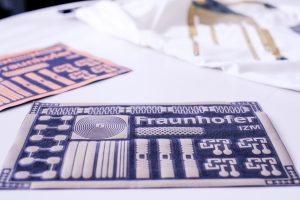

By integrating electronic components, textiles can be enhanced with many different functions such as sensors and lighting. This enables completely new application areas for textiles in an innovative and fast-growing market. Fraunhofer IZM’s research group System-on-Flex has been developing, analyzing and qualifying textile-based electronic systems for over twenty years. A main focus is innovative interconnection technologies for textile and stretchable substrates. Functionality and reliability requirements are always determined by the application in question. The Fraunhofer IZM laboratory for electronics in textiles (TexLab) and diverse equipment for microelectronics assembly and analysis provide the best preconditions for research and development.

Applications

The wide variety of electronic textiles available is matched only by the many possible applications, including in the fashion sector, to medical engineering, security and logistics, through to the lighting and construction sectors:

- Sensors integrated into clothing as part of personal safety applications

- Large-area fabric with integrated sensors for alarm systems

- Lighting and displays on and in fabric

- Textile wireless sensor nodes

- Sensors in fiber-reinforced composite materials for condition monitoring

- Textile RFID transponders for logistic

- Interactive evening dress and activewear

- Anti-theft and anti-fraud protection in clothing and textile accessories

- Occupancy sensors for vehicle seats

Technologies

We apply microelectronic processes, such as low-temperature soldering, gluing with conductive and non-conductive adhesives and non-heat based joining such as force fitting and crimping. One simple but extremely robust technique that also meets high reliability requirements is gluing using non-conductive thermoplastic adhesives.

Fraunhofer IZM also investigated electrical bonding by stitching in depth.

An alternative is offered by flexible electronic systems based on polyurethane substrates, which can be laminated onto textile substrates using conventional processes. Apart from the bonding technique, system reliability is determined by the encapsulation technology, and here the institute develops processes for liquid encapsulation and transfer and hot melt molding.

Reliability is another key issue. All systems are validated in-house according to industrial norms for parameters such as temperature, humidity, washing.

Fraunhofer IZM works with a pneumatic Lotus heat press LTS 575 because of it’s unique pressing power of up to 8 bar.

Contact

Fraunhofer-Institut für Zuverlässigkeit und Mikrointegration IZM

Dipl. Ing. (FH) Christian Dils, christian.dils@izm.fraunhofer.de

Gustav-Meyer-Allee 25, 13355 Berlin