We take responsibility for the people we supply.

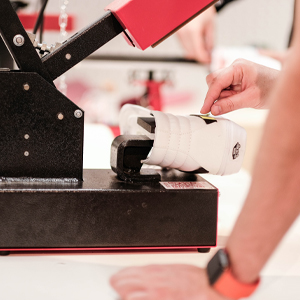

For us as heat press manufacturers, this Lotus guiding principle means above all how we can produce in a resource-conserving, environmentally friendly as well as socially acceptable way.

We believe that the best way to avoid unnecessary industrial waste is to prevent it from occurring in the first place. That is why, for 50 years now, we have been offering a conscious and value-oriented alternative to a product strategy that focuses on short-lived, inferior products and quick replacement.

Lotus builds solid and valuable machines that are still worth maintaining and whose wearing parts are also easy to replace. However, a sustainable product concept like this can only work if the necessary spare parts are quickly available and local resources can be used. This is the case with us, and we go to great lengths to ensure this.

In this way, our customers benefit in several ways. On the one hand, through durable products that efficiently contribute to the value creation of the company and, on the other hand, through fast service-oriented problem-solving in case of equipment failures. This is good for our customers and good for the environment.

A top priority at Lotus is given to those measures that keep the carbon footprint of Lotus heat presses as low as possible. These include:

1. Local production

An important component of the sustainability concept at Lotus is the local production of the Lotus heat presses in the Italian Lombardy region or in the greater Milan area. Considering that a large proportion of the transfer presses used in the EU come from China, it is clear that local production is a particularly important step towards greater sustainability and responsibility for our environment. For this reason, the resources required for the production of Lotus heat presses are also supplied as close as possible to the production site. I.e. for the most part regionally and nationally. Some of the high-quality components come from Germany.

2. Low energy consumption

Our highly efficient heating system leads to an energy-saving operation of a Lotus heat press compared to many presses of competitors.

3. Long service life

Lotus manufactures solid, long-lasting, valuable machines that can last decades if maintained.

4. Extending of service life

In order to further extend the service life of Lotus heat presses, we offer maintenance and repair services

5. Reusable components

We mainly use recyclable materials such as iron and aluminum. Plastics are reduced to a minimum.

6. High social standards

We offer all employees good and safe working conditions in compliance with exemplary European social standards.

Further, planned measures

- Use of renewable energies

- further optimization of energy and material efficiency

- further measures for material recycling and reuse

If you have any questions about our heat presses, please contact us at info@lotustransfers.com